|

Our solution

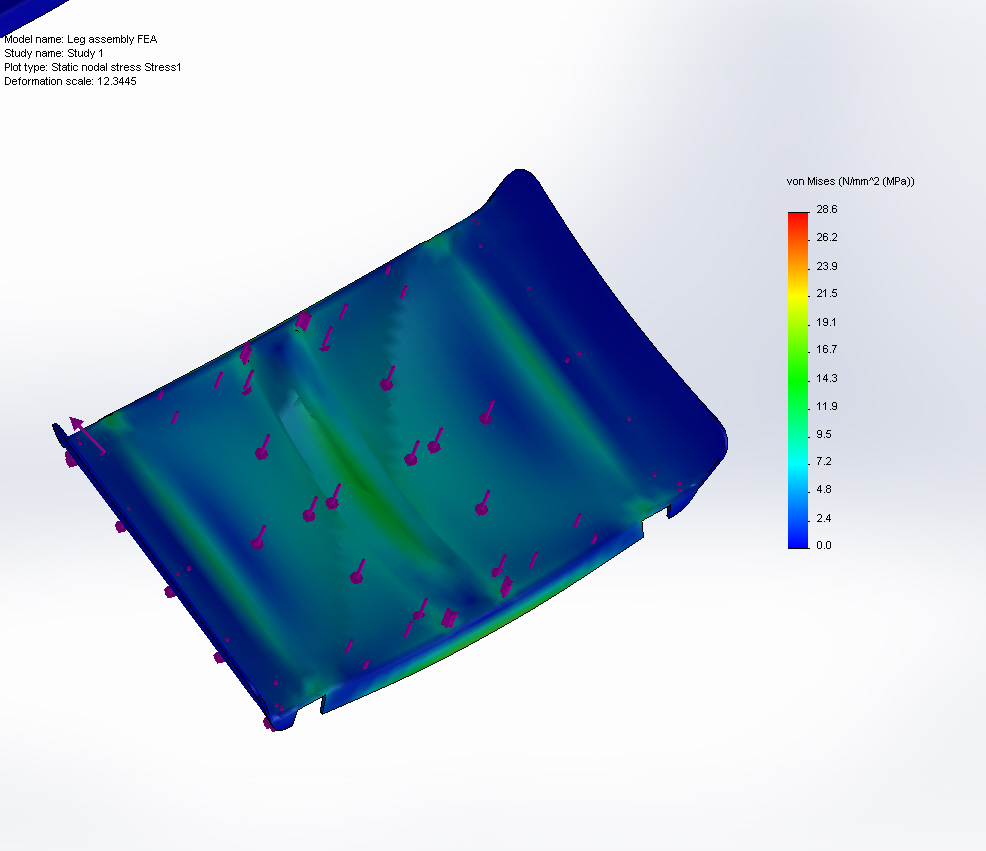

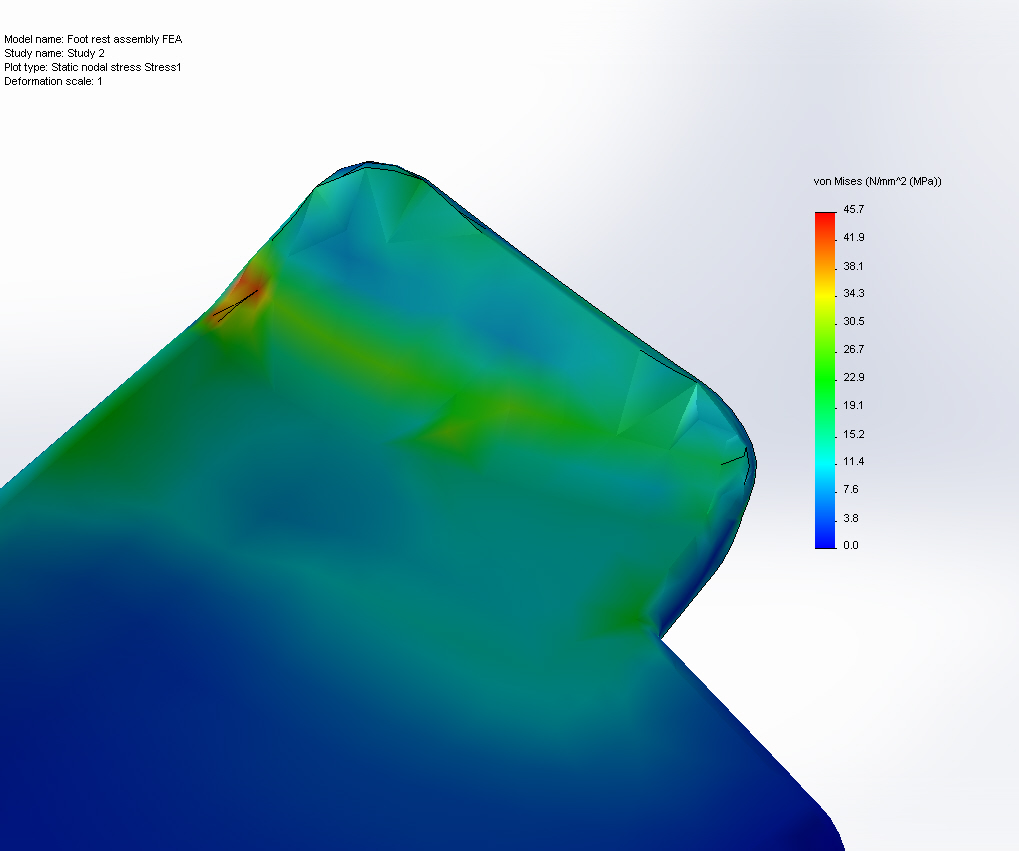

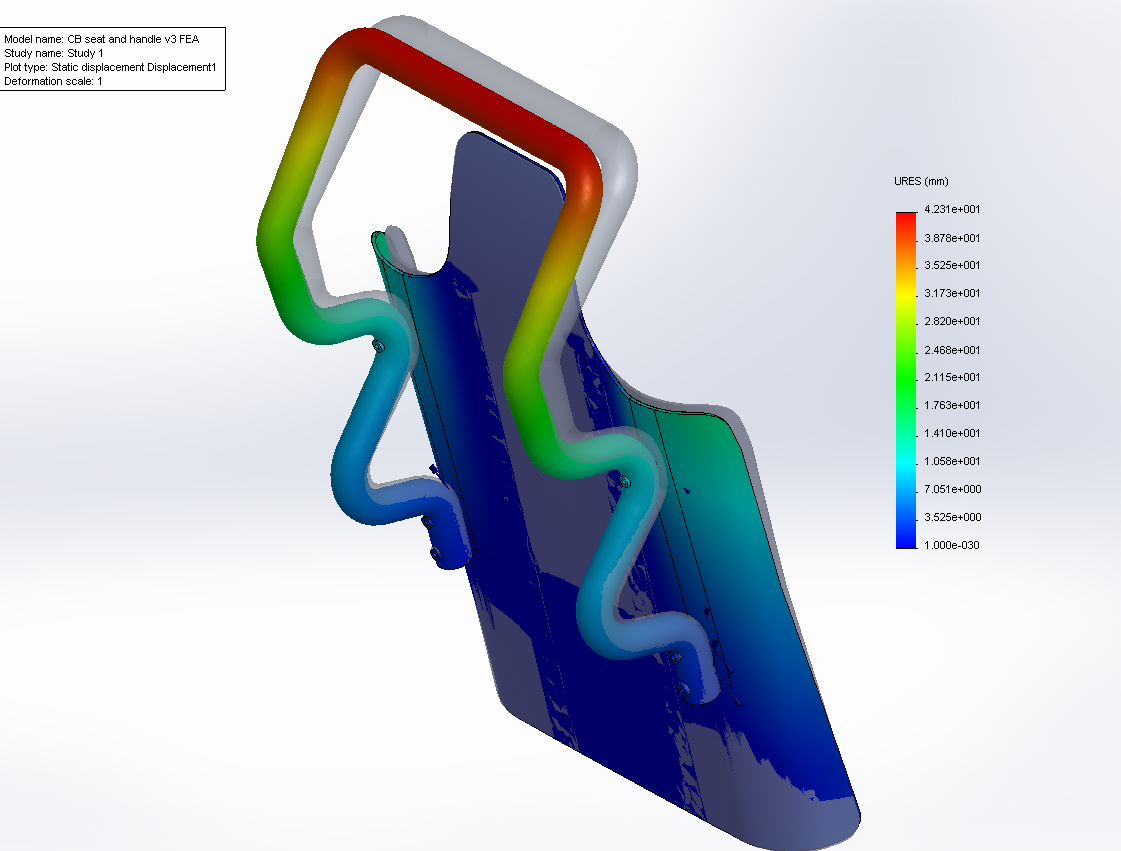

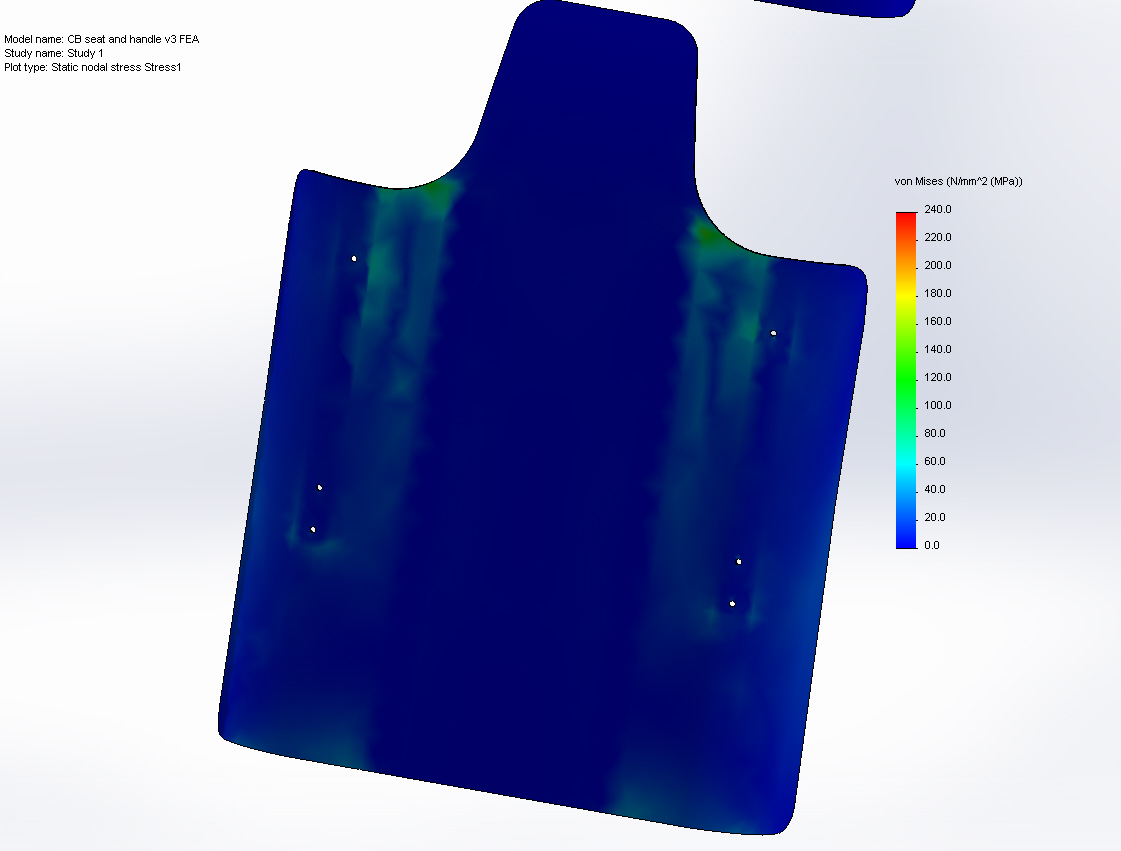

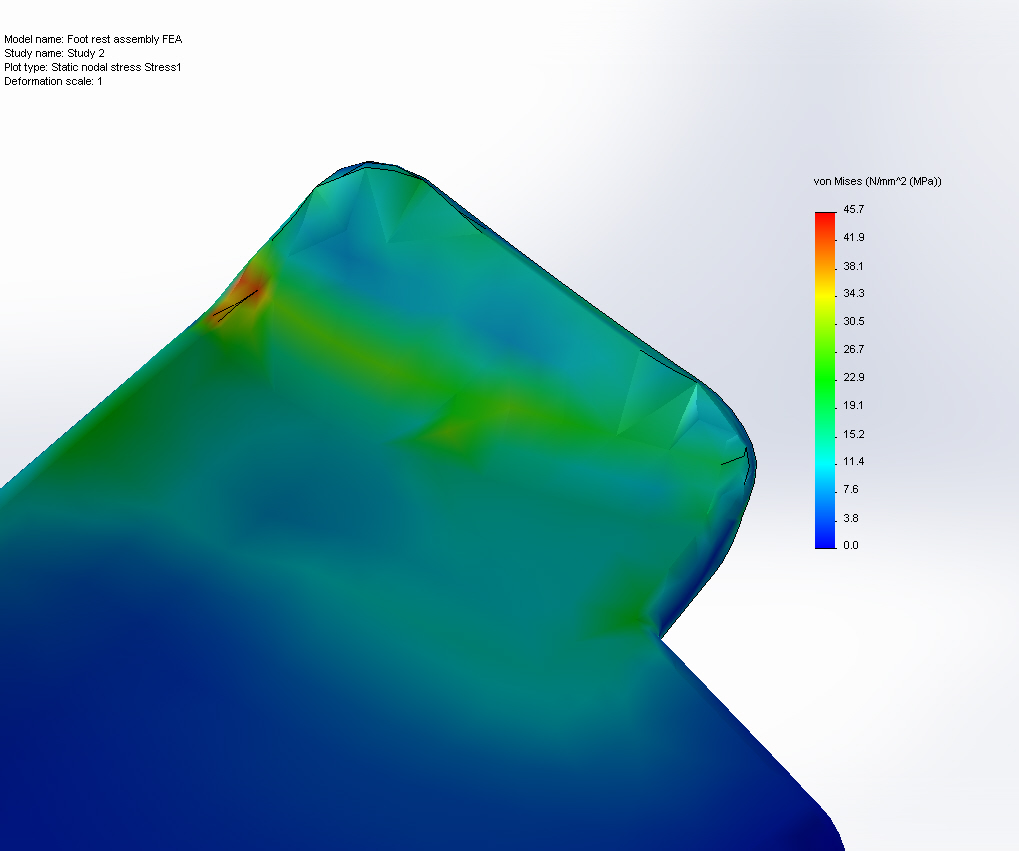

When sandwich panels carry a large load, or are highly

stressed, our consultants would normally conduct a laminate

stack analysis. This checks that none of the laminae is

overloaded, that they will not delaminate and that the

core is not overloaded by its shear stress. In this case,

the mechanical panels were not that highly loaded. Our

consultants built an FEA model of

each panel, using solid elements for the core and shell

elements for the skin. Although numerically bonded together,

we could display the stresses separately in the cores

and skins. Our consultants used the FEA

models to design the core and laminate thicknesses.

|