The problem

No mechanical structure is completely rigid, so when

we were approached by a customer asking for one, we were

a little surprised. A box was needed, to hold optical

components for scanning a distant object in 3D. Because

the technology relies on measuring phase differences in

light, the mechanical structure needed to hold the components

stationary to within a few microns and micro radians.

Thatís pretty close to rigid. The product had different

options, so the mechanical structure also had to be modular

and quickly assembled without any special tools. The customer

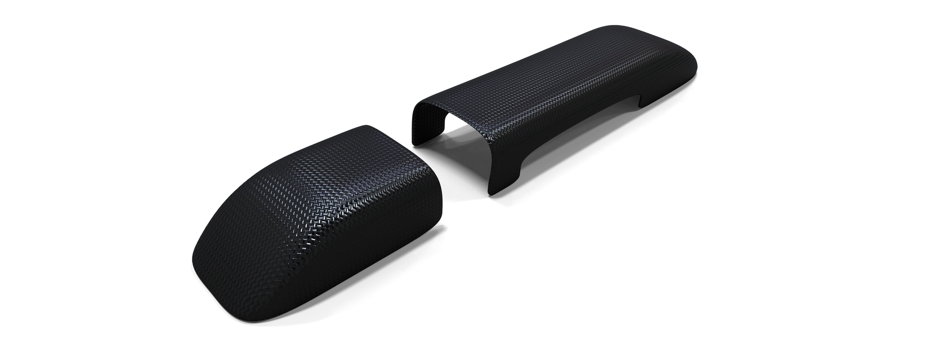

wanted to improve on an existing carbon fibre model. Coupland

Bell consultants were asked to produce a concept design,

in conjunction with a design agency.

|

|

|

Our solution

Carbon fibre was the clear choice for a structure

that would be reasonably light, very rigid and be as thermally

stable as we could reasonably make it. The main problem

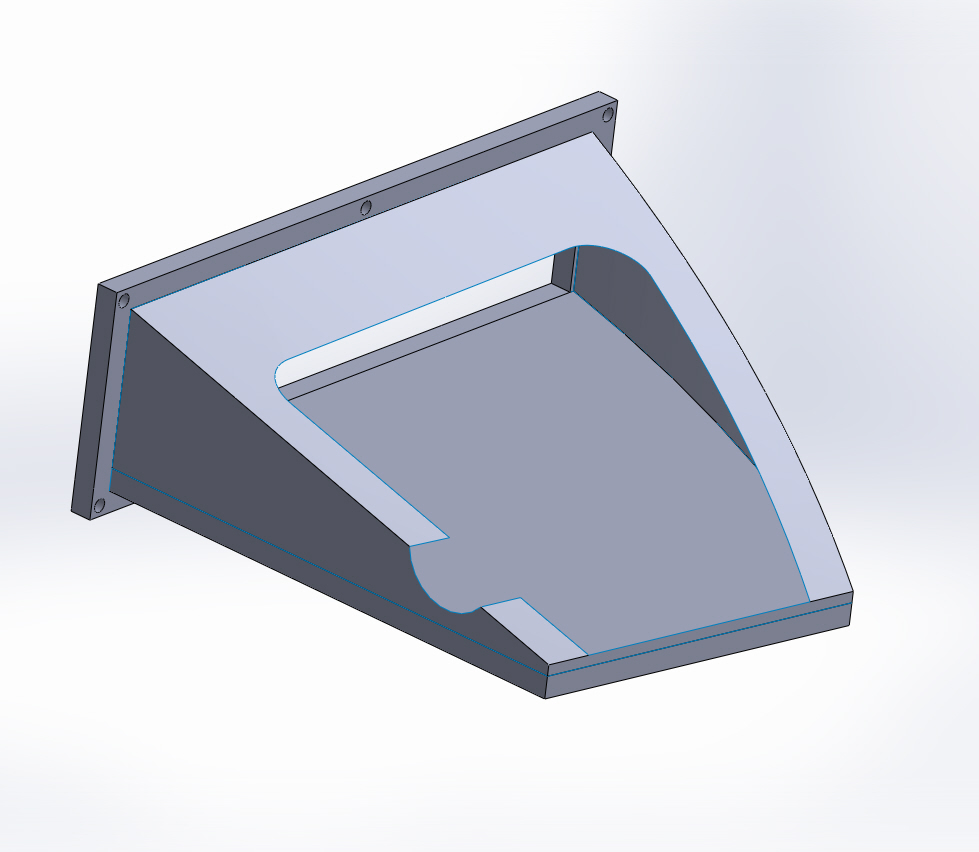

was that a projector would be mounted in a central box,

resting on a tripod stand and a camera would be mounted

in a separate module cantilevered from its side. The camera

could be mounted on either side. This aspect of the design

had already been fixed. This made the loads asymmetric with

the supports, introducing a twist that would be hard to

control to within micro radians.

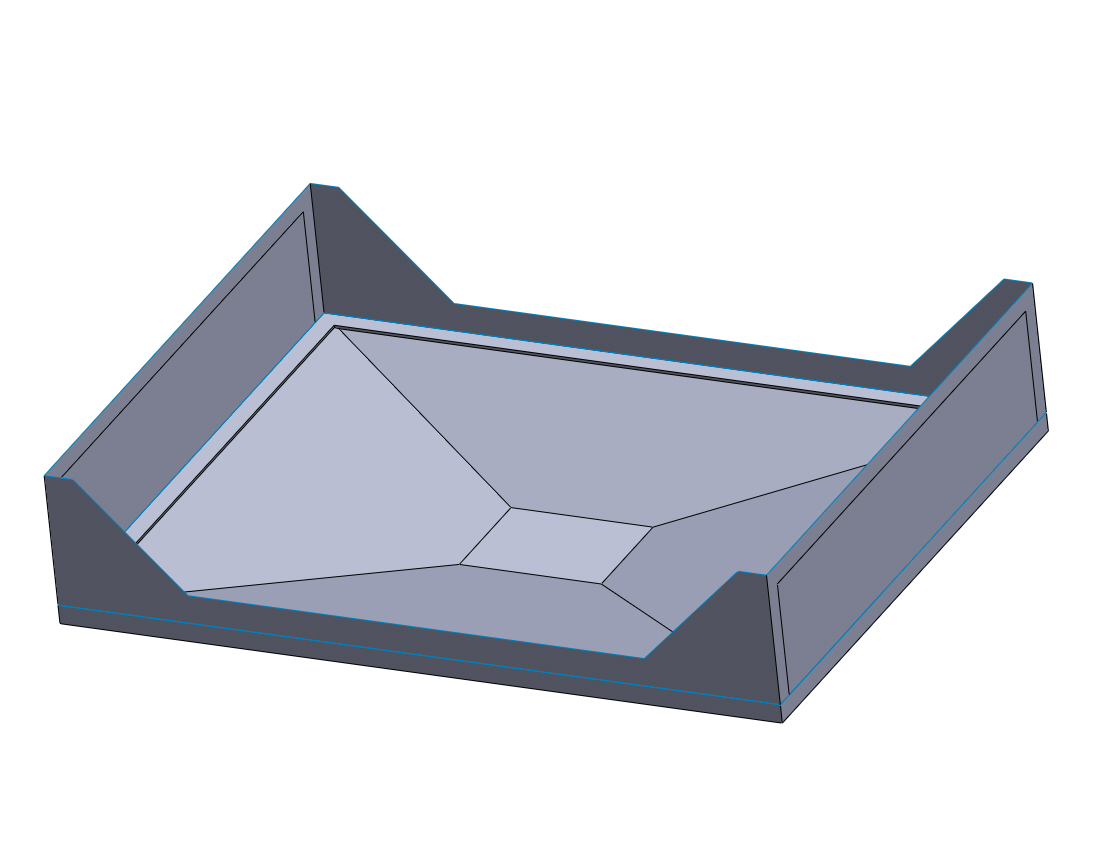

Our consultants solution was to mount the projector

within a cradle. The cradle and camera support would be

separately mounted to a rigid structure on the tripod.

This allowed the projector and camera to move together

under gravity and thermal loads and balanced the twisting

effect. Various different concepts for the mechanical

structures were tried using FEA,

leading to a simple cost-effective solution. For the quick

assembly joints, our consultants modelled dove tails,

fir trees, nested cylinders and tapered joints. The performance

of each was quantified, leading to a table comparing the

performance, advantages and disadvantages of each type,

helping our customer decide which to use.

|