Our solution

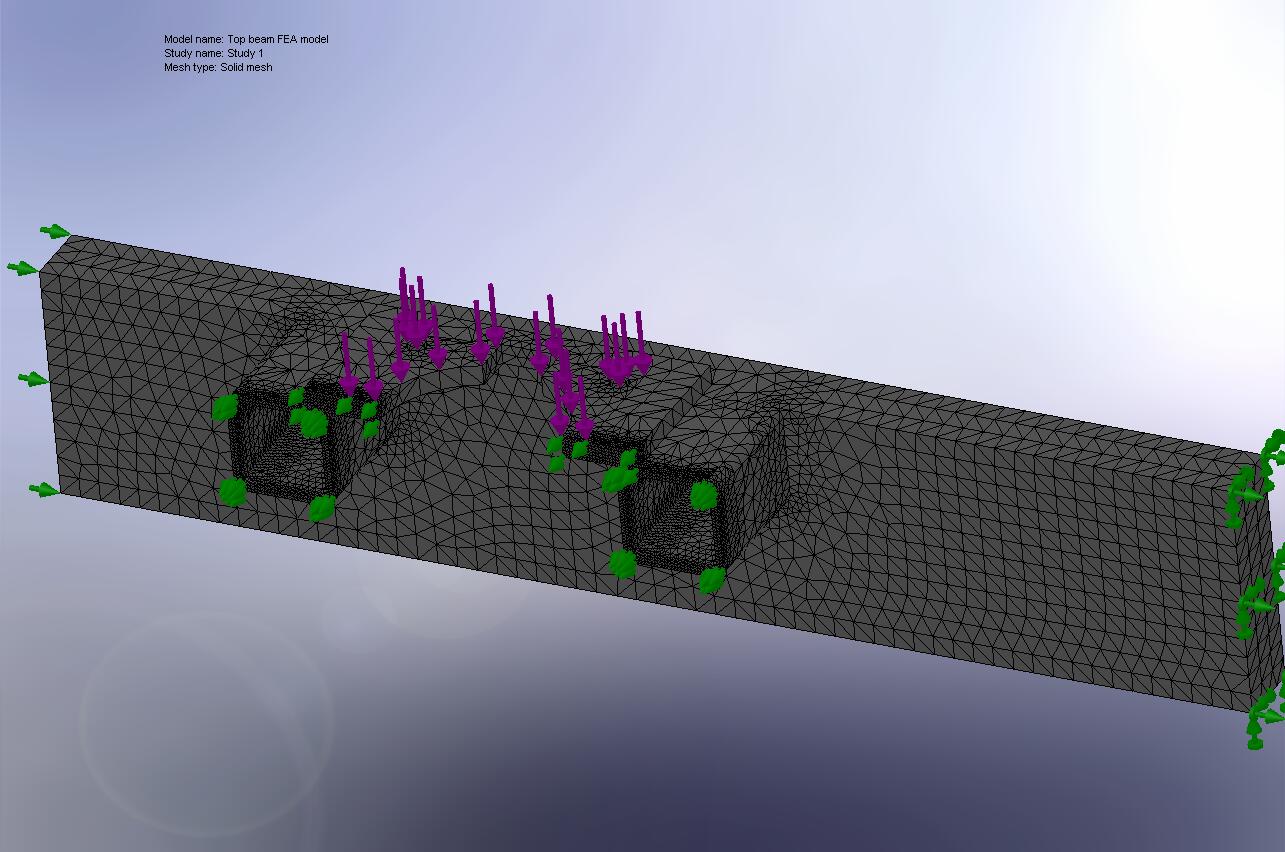

Our consultants could have used a hand calculation to

show the beam did not need to be solid, but large forces

from the ram were carried by substantial welded plates

on its side web. These were also welded to perpendicular

box beams, making the loads asymmetrical, so our consultants

built an FEA model of quarter of

the assembly.

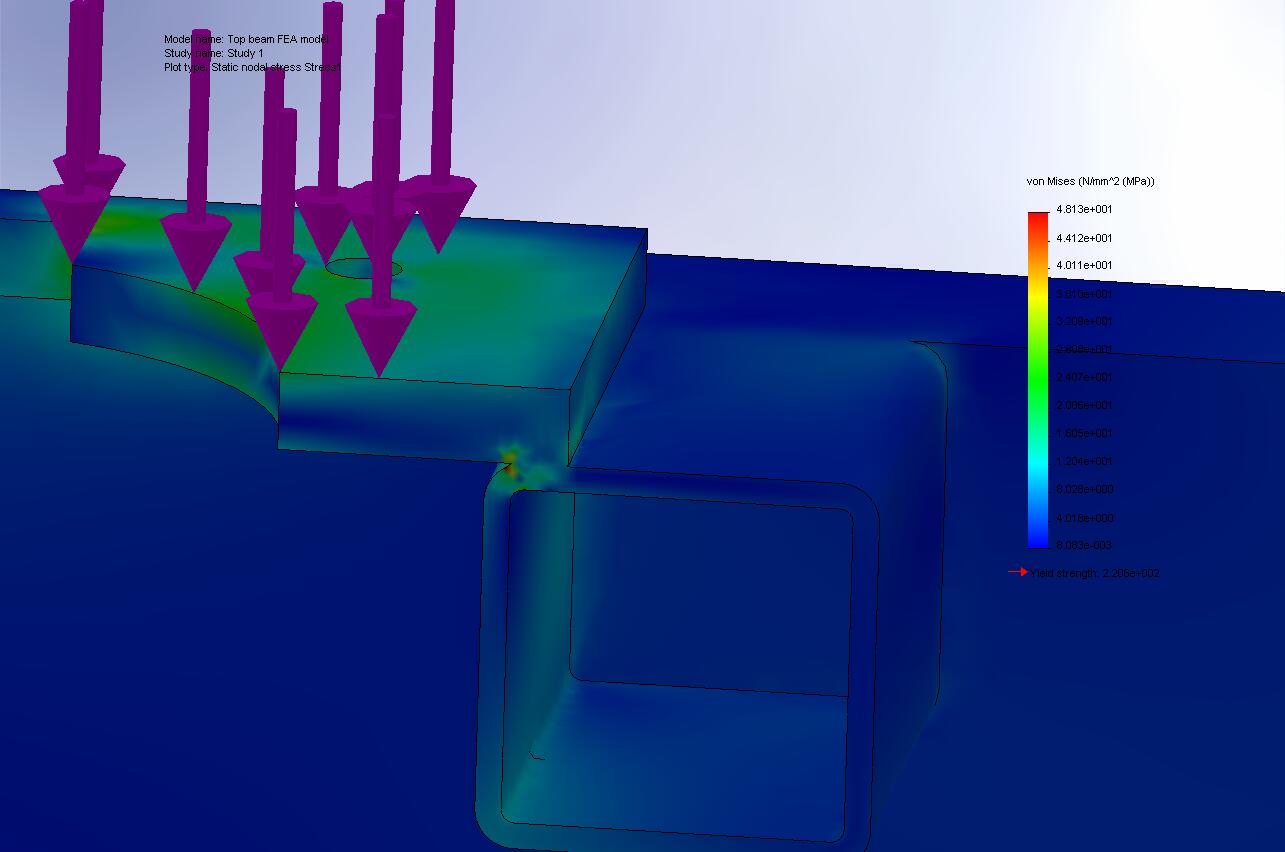

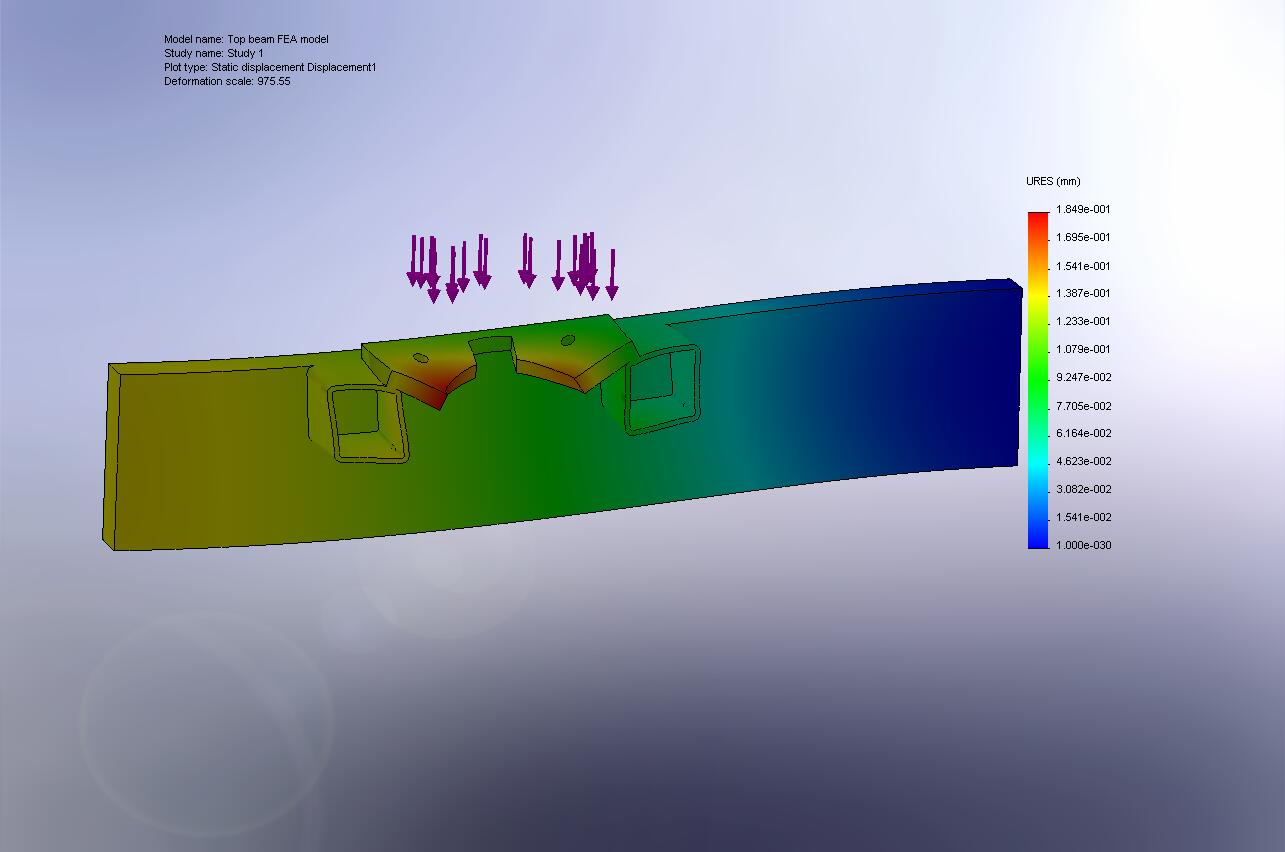

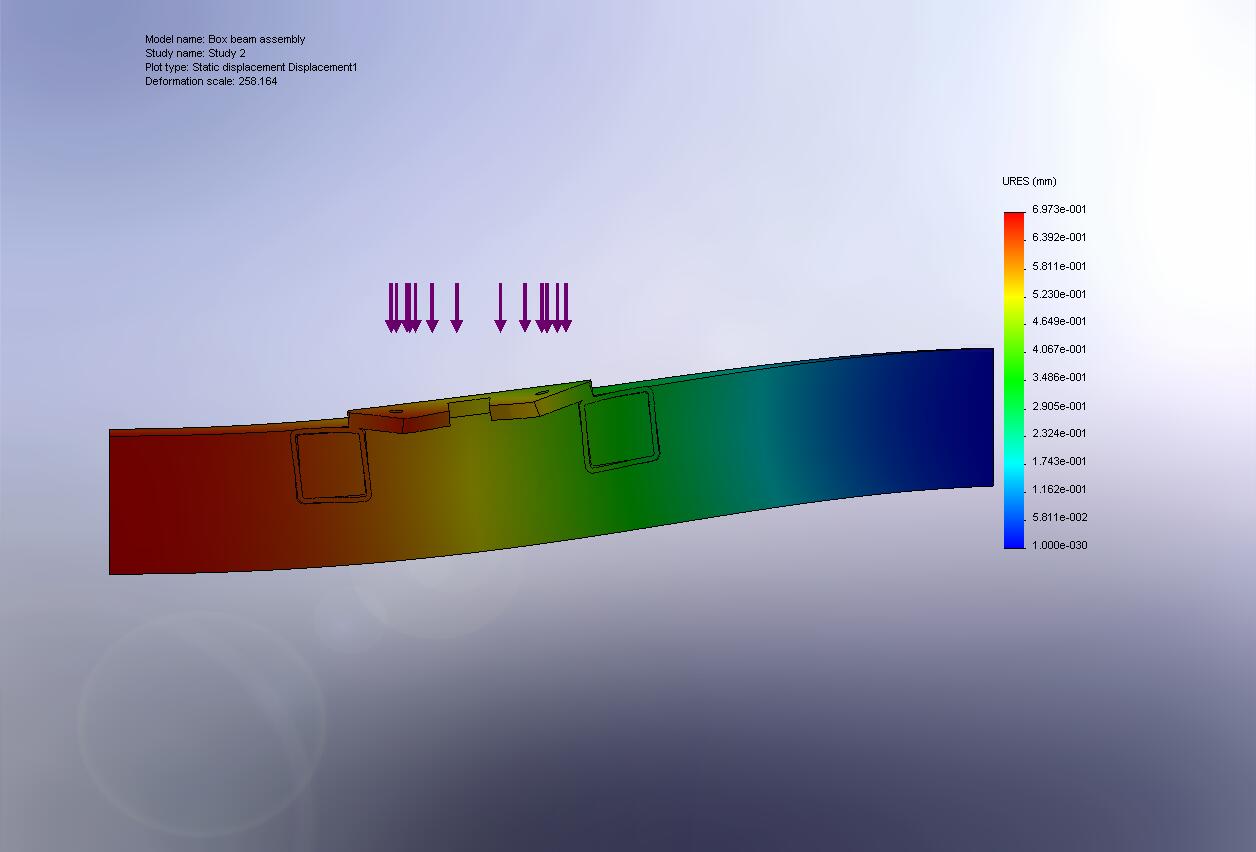

Our consultants used solid elements with symmetrical

boundary conditions to represent the parts we had not

modelled. This confirmed that the stresses and deflections

were low in the beam and acceptable in the plates and

box beam. Our consultants then redesigned the beam as

a box section and built a new FEA

model.

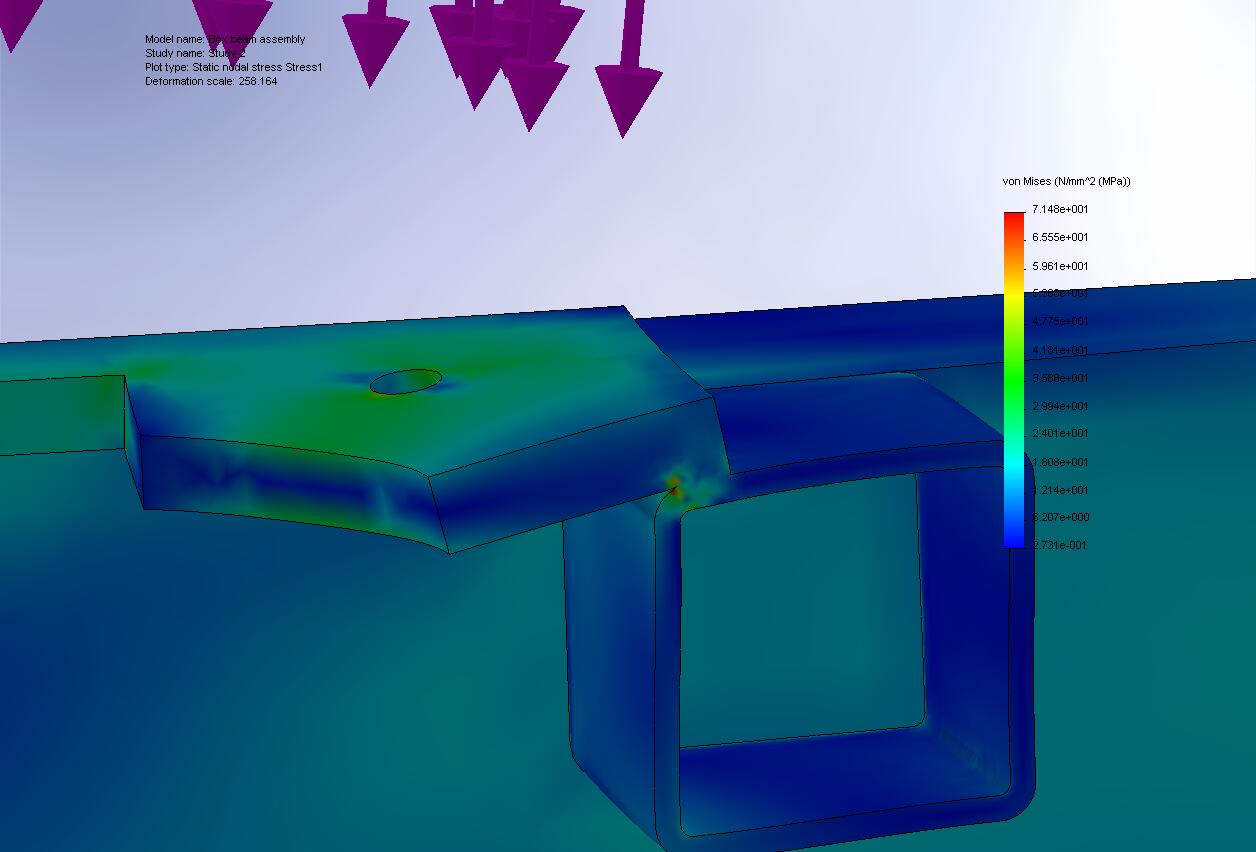

Our consultants used shell elements for the new beam

but retained the solid elements for the plates and original

box beams, where the stresses were more complicated. The

new design shared the stresses more evenly and had an

adequate factor of safety. This was much lighter and cheaper

to make than the original.

|