|

Our solution

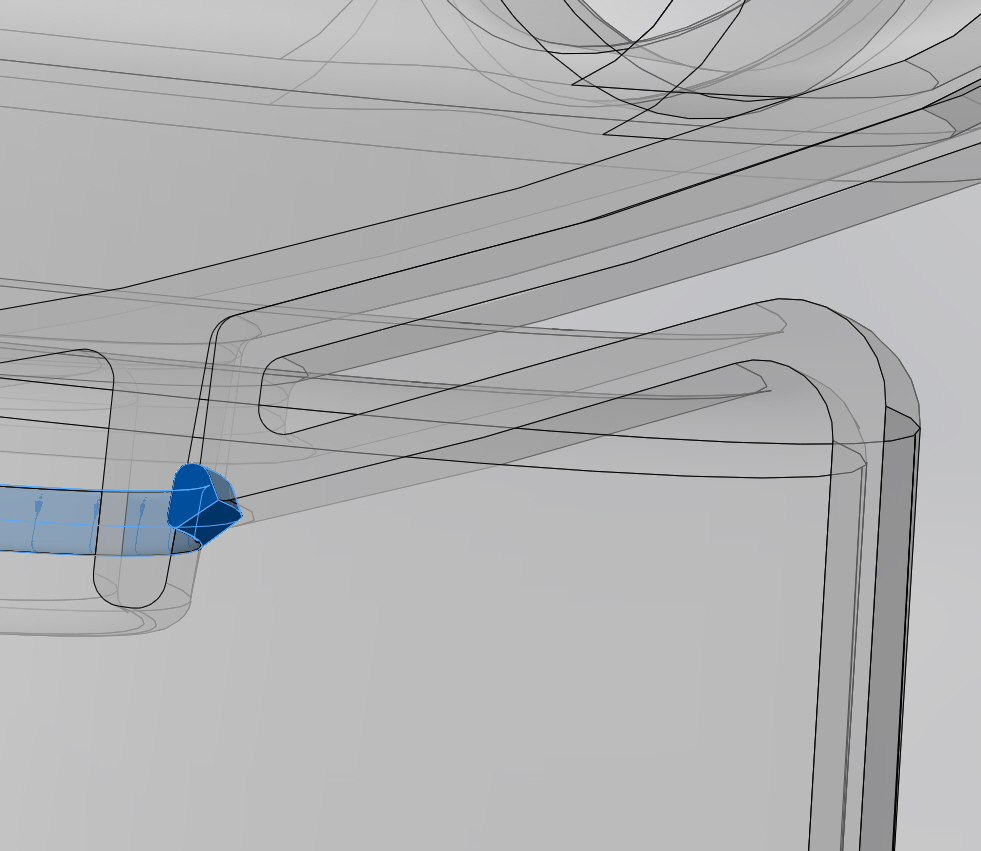

There were 2 welds to consider, running around an outer

circumference and an inner one. The tank was asymmetric

so we could not model a segment of it. Our consultants

built an FEA model of the tank and

base using shell elements and loaded them to understand

the gross stresses and deflections. This allowed us to

chose a plane to cut the tank, where there were no deflections

and build a more detailed FEA model

of the remaining portion using solid elements.

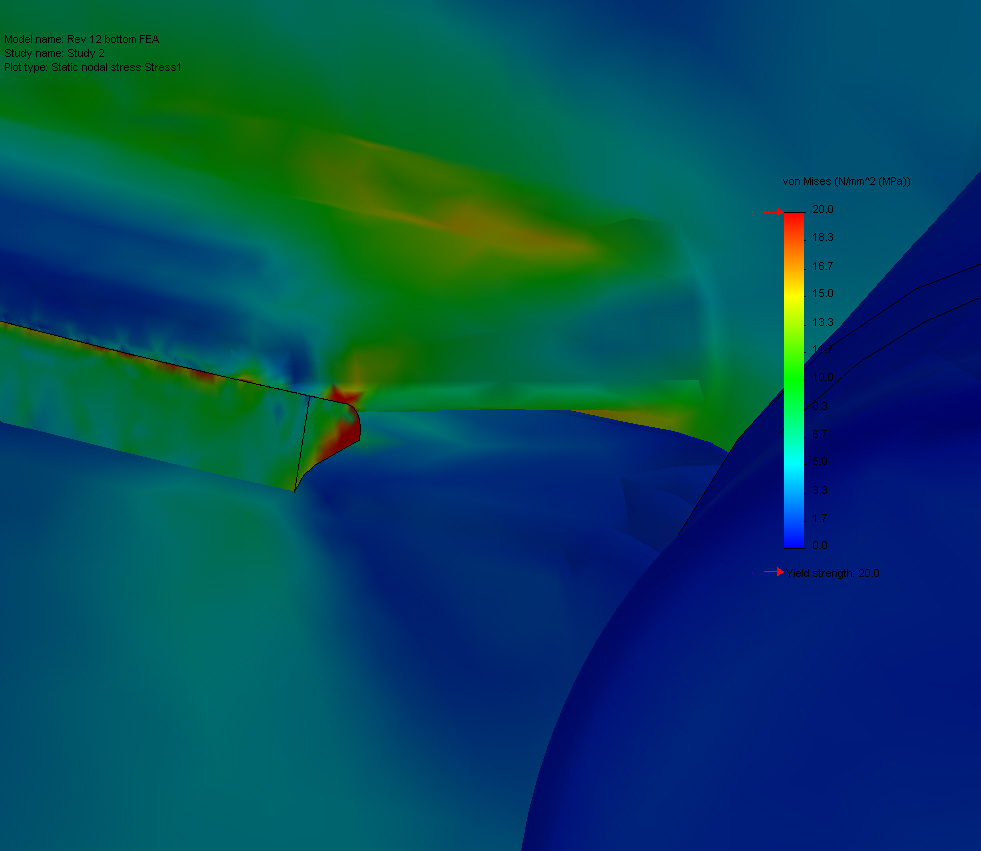

Having taken advice from the supplier of the weld gun,

our consultants modelled the weld bead, including its

outer face and its typical penetration into the melted

surfaces below. We predicted the residual stresses from

the welding process using a thermal boundary condition

on the weld. Finally, the loads on the tank were added

in, so the weld stresses could be predicted. The results

showed that the weld stresses may lead to long-term cracking

and failure. The design loads on the tank were then limited

to a safe level, to give adequate performance from the

welded joint.

|