|

|

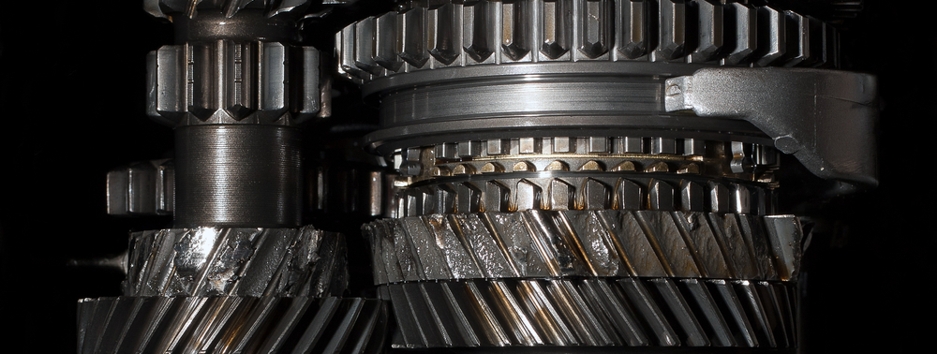

Services - Mechanical failure analysisA product that never fails is likely to have a large factor of safety, or be ‘over-designed’. ‘Over designed’ products can be unnecessarily heavy or expensive to make. Most designers will face some type of component failure at some point, as they attempt to develop a product and control cost. Some are simple and easily cured and many are more complicated. Typical causes of mechanical failure include:

These factors can often work together. High cycle fatigue due to vibration or resonance, followed by a static stress failure is common, but there are many possible interactions. Mechanical failure analysis can help to identify the cause or causes and quantify what happened. It should lead to predictions about when or if it will happen again and what to do about it, leading to a better design. This normally needs a combination of Coupland Bell’s site services and calculations or finite element analysis (FEA). Our consultants experience includes finding the causes of:

|

Enquiry Form |

|

|

|

|

© Copyright 2016 Coupland Bell Ltd. | All rights reserved. UK Mechanical Failure Analysis Consultants. |