|

|

Mechanical failure analysis of cracked HDPE moulding

The problem

Rotational moulding in high density polyethylene, HDPE,

can be very cost effective for large mouldings.

It is often used for tanks, street furniture and industrial

casings, as well as marine products. The design

details, particularly structural ribs and reinforcing

features, are heavily constrained by the manufacturing

process. This is because the HPDE enters the mould

as a powder and it gets distributed around the inside

as it is tumbled by the mould. The wall thickness

is not even and may be too thin or thick in corners and

parts of the mould where the material isn't evenly distributed

leading to mechanical failure.

|

|

|

Our consultants were approached by a company making casings

for an industrial product, after a casing suffered a mechanical

failure. The casing had cracked along a corner when

the casing had been under a negative pressure.

Our solution

At the outset it wasn't clear whether the mechanical

failure (crack) was a due to a design fault or a manufacturing

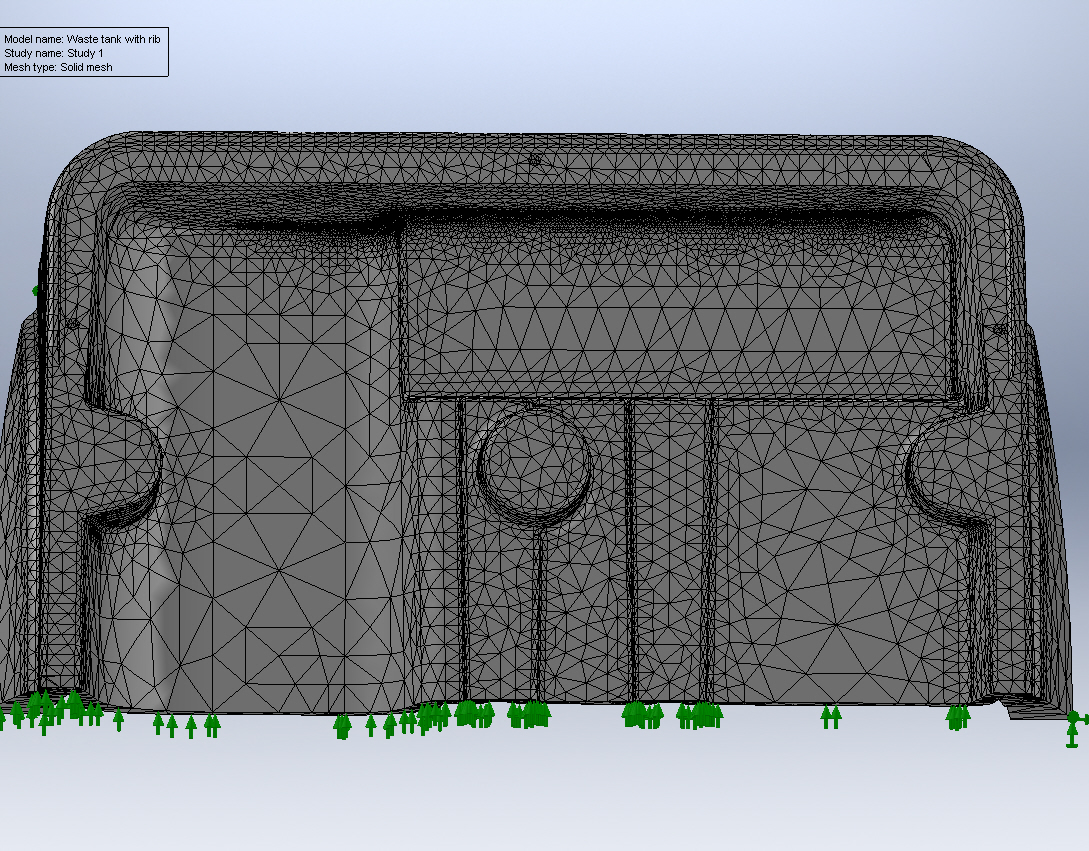

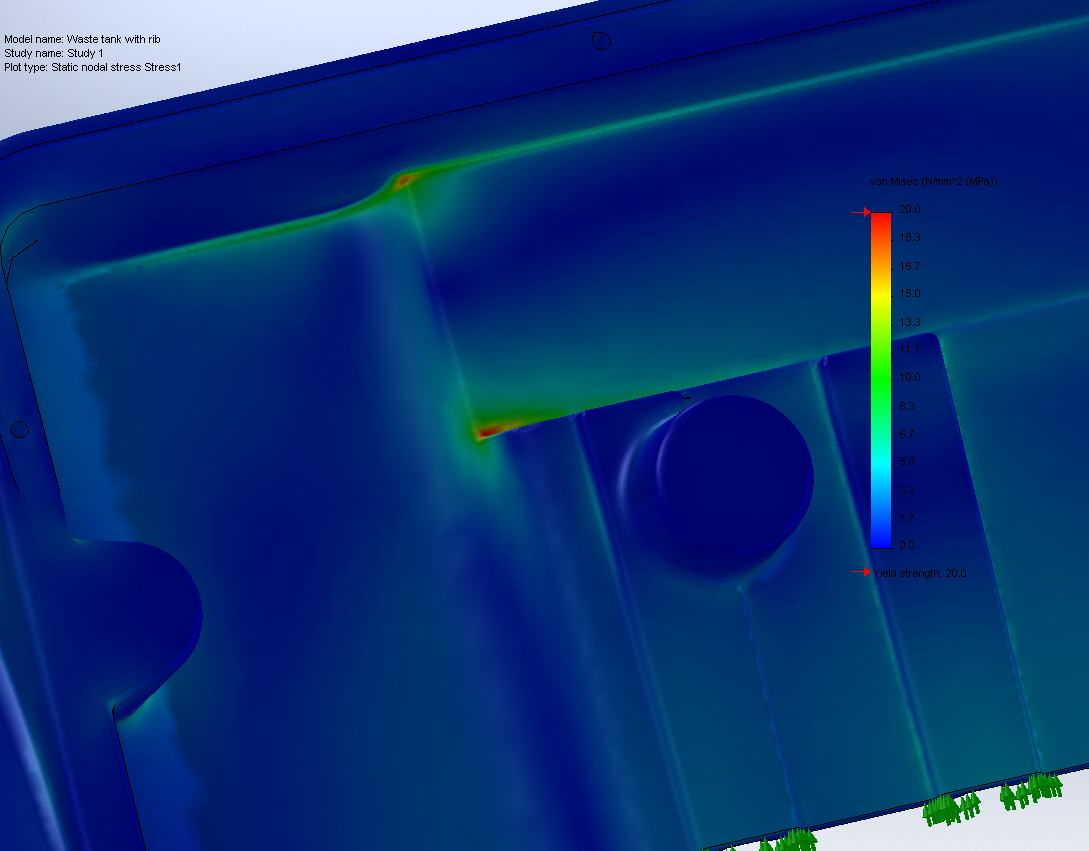

fault. Our consultants built a finite

element analysis model of a portion of the casing,

with a fine mesh in the area of the crack. FEA

showed that the casing would not have cracked if it was

the correct thickness and it was unstressed when it left

the factory.

|

|

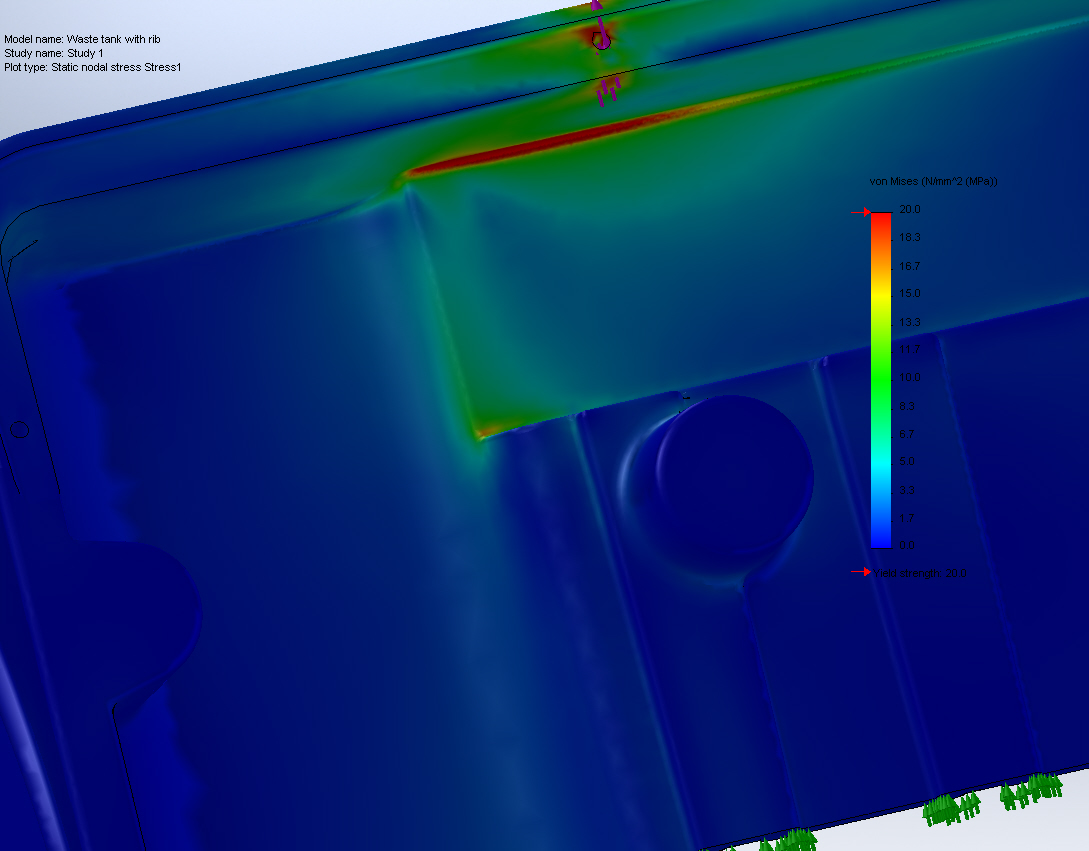

A sample casing was cut up and this showed that the local

thickness was not correct. Our consultants then

modelled the cooling process and found a high residual

stress at the cracked corner, due to the manufacturing

process. The combination of the residual stress

and incorrect thickness were enough to cause mechanical

failure under negative pressure.

Minor changes to the structural details can often solve

this sort of problem. Metal plates or reinforcing

bars can sometimes be incorporated into rotational mouldings.

In this case, the client took the opportunity to design

an improved product and our consultants assisted with

the structural design of an improved casing, which has

not failed.

|

|